Tempering is a heat treatment process used to reduce brittleness and improve the toughness of steel, as well as to relieve the stresses induced during the quenching process after hardening. It involves reheating the hardened steel to a temperature below its critical transformation range (typically between 150°C and 650°C), followed by cooling. This process allows the steel to achieve a balance between hardness and ductility. The material is heated to a specific temperature, held at that temperature for a designated period to refine its microstructure, and then cooled to attain the desired mechanical properties, including optimal hardness and toughness.

Industries Served:

Fasteners Industry

Aerospace Industry

Material Grades That Can Undergo The

Tempering

Material

High-Speed Steels, Alloy Steel, Carbon Steel

Material Grade

AISI M2, AISI T1, AISI 4140, AISI 4340, AISI 1045, AISI 1080

Tempering Furnaces

Chamber Furnace

HIGHTEMP's Chamber Furnace is a reliable solution for batch heat treatment, offering excellent temperature uniformity and precise control. Its robust design ensures durability and consistent performance, making it suitable for various applications. The furnace is engineered for efficiency, delivering high-quality results with optimal energy usage.

Pit Type Furnace

Pit Furnace, also known as Pit-type Furnace, is an Industrial furnace used for heat treatment processes such as annealing, tempering, and hardening. The Pit Furnace is designed as a deep vertical cylindrical or rectangular chamber which can accommodate various sizes and shapes of materials. HIGHTEMP’s Pit Furnace is typically installed in a pit or deep chamber either below ground level or at ground level, which allows for easy loading and unloading of components.

Batch Furnace

HIGHTEMP offers advanced Batch Furnace solutions, designed to meet the specific heat treatment needs of various industries. Our Batch Furnaces provide reliable and uniform heat treatment for a range of materials, ensuring superior quality and durability. Our models include Roller Driven Batch Furnace, Two Tray Roller Hearth Carburising and Hardening Furnace, and Carburising and Hardening Furnace, offering flexibility and optimal performance.

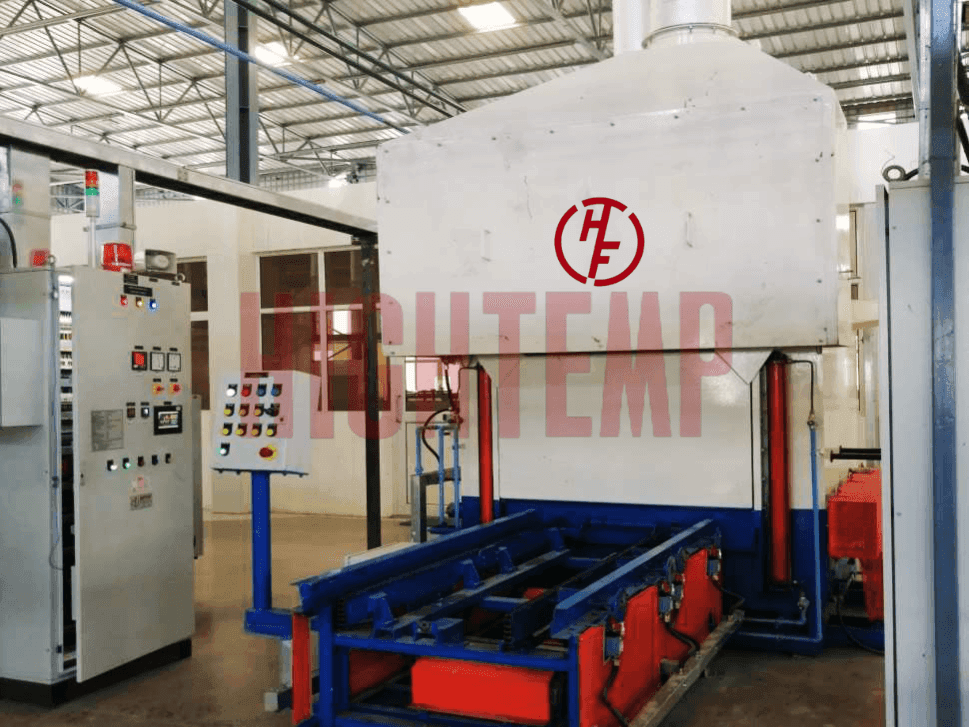

Bogie Hearth Furnace

HIGHTEMP's Bogie Hearth Furnace is designed for the heat treatment of heavy and large components. Equipped with a bogie, the furnace simplifies the loading and unloading process, making it ideal for applications requiring precision and uniform heating. The insulation and efficient heating systems ensure energy savings while maintaining superior performance. This furnaces can be customized with single or double doors and single or double bogies to meet specific user requirements. Materials are loaded onto the bogie using an EOT crane or mechanical devices, and the loaded bogie is moved into the furnace via an electro-mechanical rack-and-pinion or rope-and-drum bogie drive mechanism, ensuring smooth and efficient operation.

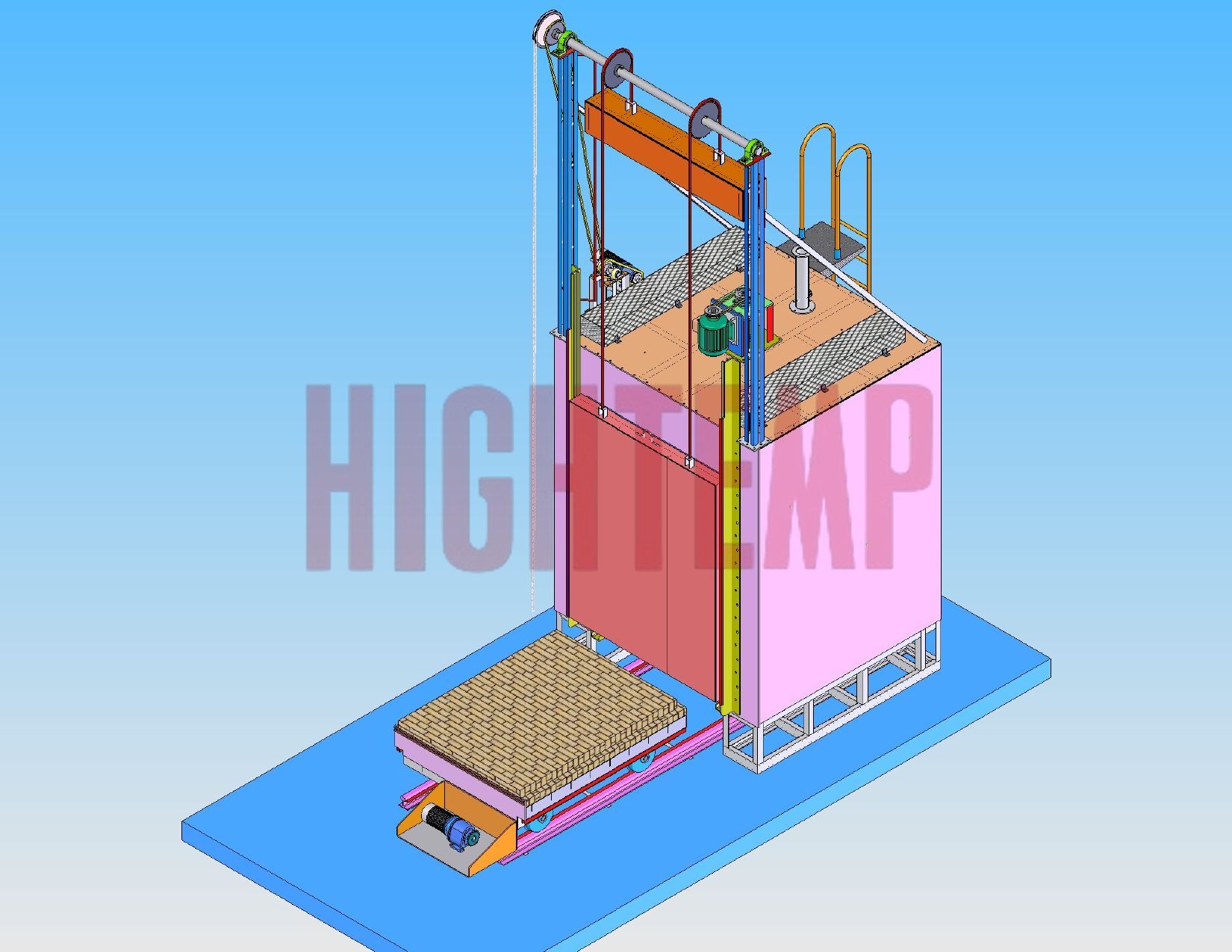

Pit Type Tempering Furnace

HIGHTEMP's Pit Type Tempering Furnace is a specialized heat treatment furnace designed for tempering large or long components in a vertical configuration. Ideal for aerospace, automotive, and industrial manufacturing applications, this furnace provides uniform heating and precise temperature control to enhance the mechanical properties of metals. Operating within a typical temperature range of 150°C to 750°C. Equipped with advanced heating systems and temperature uniformity, the Pit Type Tempering Furnace is a reliable solution for achieving consistent results in heat treatment.