Post Weld Heat Treatment is often used for steel structures in the automotive and aerospace industries as it ensures reliability and performance of components.

Industries Served:

Fasteners Industry

Gears Industry

Trucking/Bus / Rail Industry

Material Grades That Can Undergo The

Post-Weld Heat Treatment

Material

Carbon Steel, Alloy Steels, Titanium Alloys

Material Grade

ASTM A36, A516 grade 70, A572 grade 50, ASTM A336 P11 and P22, A 234, SAE 4140, Ti-6Al-4V Grade 5

Post-Weld Heat Treatment Furnaces

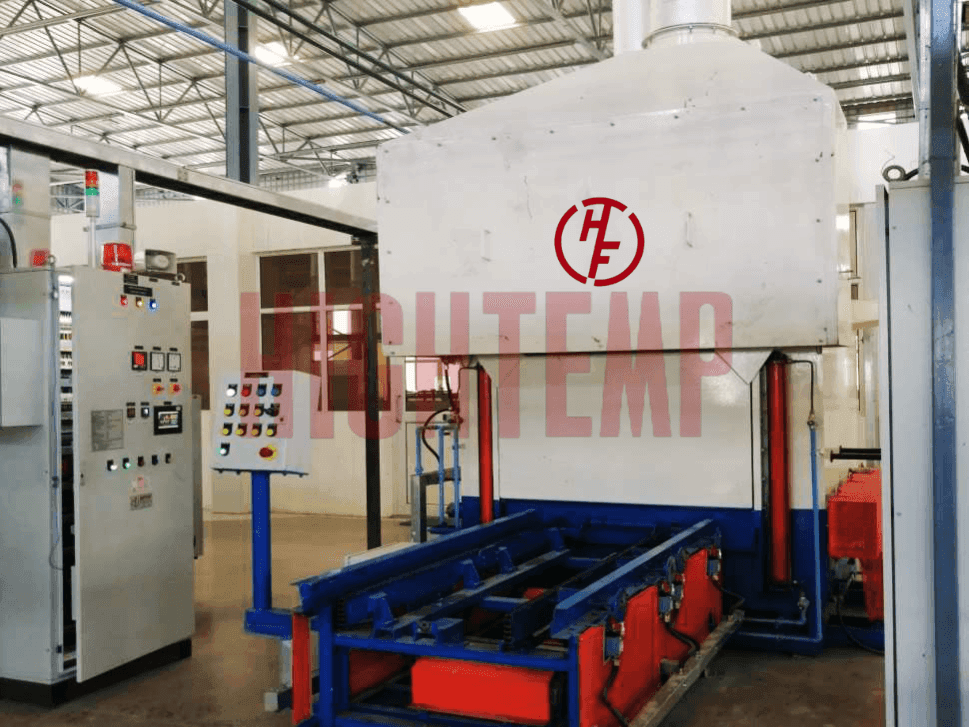

Chamber Furnace

HIGHTEMP's Chamber Furnace is a reliable solution for batch heat treatment, offering excellent temperature uniformity and precise control. Its robust design ensures durability and consistent performance, making it suitable for various applications. The furnace is engineered for efficiency, delivering high-quality results with optimal energy usage.

Drop Bottom Furnace

A Drop Bottom Furnace (DBF) is an industrial furnace used for various heat treatment processes. HIGHTEMP’s DBF consists of the furnace chamber, drop bottom and a quenching tank. The key feature is that the furnace is placed above so that the quenching tank can be positioned directly below the furnace.

Pit Type Furnace

Pit Furnace, also known as Pit-type Furnace, is an Industrial furnace used for heat treatment processes such as annealing, tempering, and hardening. The Pit Furnace is designed as a deep vertical cylindrical or rectangular chamber which can accommodate various sizes and shapes of materials. HIGHTEMP’s Pit Furnace is typically installed in a pit or deep chamber either below ground level or at ground level, which allows for easy loading and unloading of components.

Batch Furnace

HIGHTEMP offers advanced Batch Furnace solutions, designed to meet the specific heat treatment needs of various industries. Our Batch Furnaces provide reliable and uniform heat treatment for a range of materials, ensuring superior quality and durability. Our models include Roller Driven Batch Furnace, Two Tray Roller Hearth Carburising and Hardening Furnace, and Carburising and Hardening Furnace, offering flexibility and optimal performance.

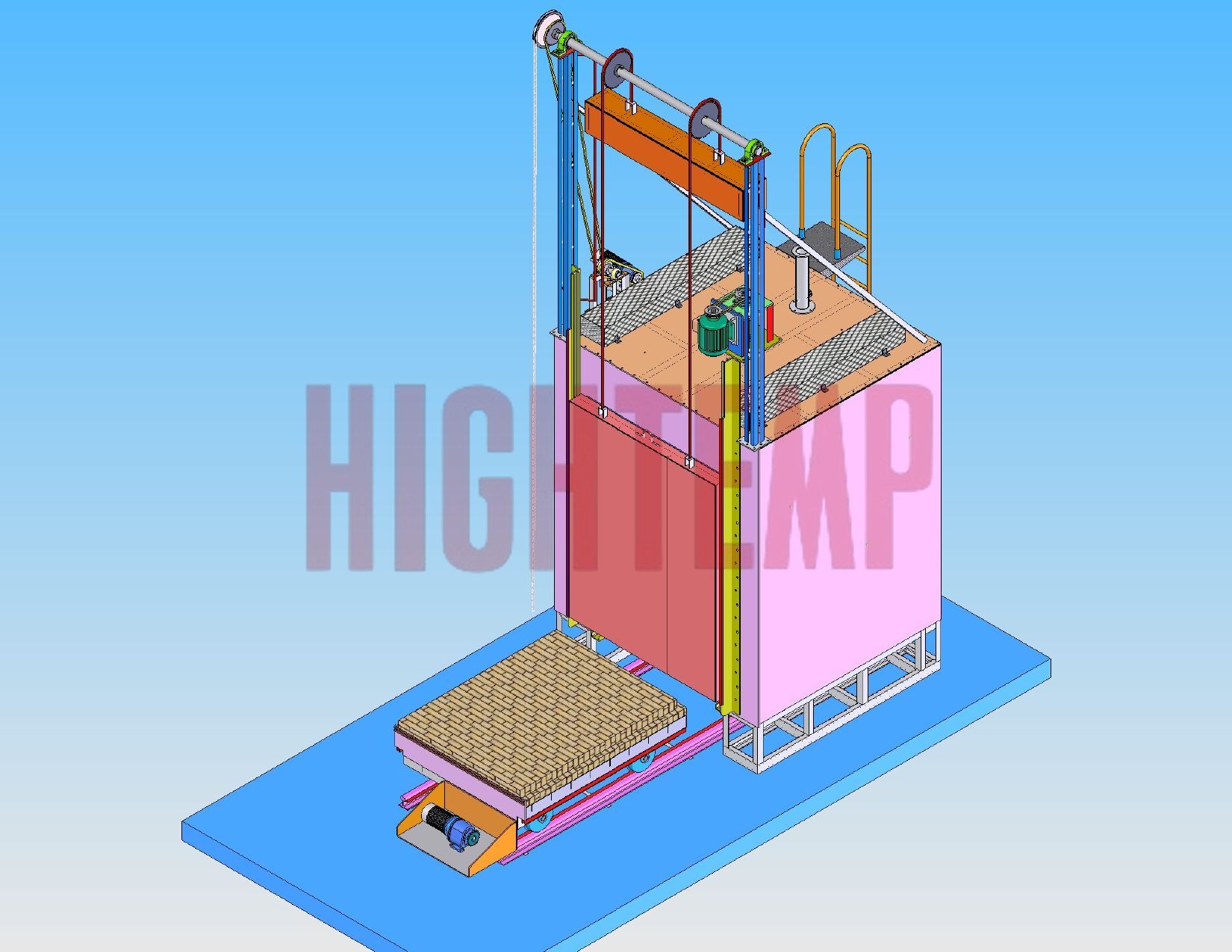

Bogie Hearth Furnace

HIGHTEMP's Bogie Hearth Furnace is designed for the heat treatment of heavy and large components. Equipped with a bogie, the furnace simplifies the loading and unloading process, making it ideal for applications requiring precision and uniform heating. The insulation and efficient heating systems ensure energy savings while maintaining superior performance. This furnaces can be customized with single or double doors and single or double bogies to meet specific user requirements. Materials are loaded onto the bogie using an EOT crane or mechanical devices, and the loaded bogie is moved into the furnace via an electro-mechanical rack-and-pinion or rope-and-drum bogie drive mechanism, ensuring smooth and efficient operation.