Gas nitriding is a thermochemical surface treatment process that introduces nitrogen into the surface of steel or other metals to form nitrides, which improve the material's hardness, wear resistance, fatigue strength, and corrosion resistance

Industries Served:

Forging Industry

Material Grades That Can Undergo The

Nitriding

Material

Carbon Steels, Alloy Steels

Material Grade

AISI 1045, AISI 1080, AISI 4140, AISI 4340

Nitriding Furnaces

Pit Type Furnace

Pit Furnace, also known as Pit-type Furnace, is an Industrial furnace used for heat treatment processes such as annealing, tempering, and hardening. The Pit Furnace is designed as a deep vertical cylindrical or rectangular chamber which can accommodate various sizes and shapes of materials. HIGHTEMP’s Pit Furnace is typically installed in a pit or deep chamber either below ground level or at ground level, which allows for easy loading and unloading of components.

Nitriding Furnace

Nitriding Furnace by HIGHTEMP is a pollution-free furnace for soft nitriding of metals. The components are treated at a lower temperature than the A-1 transformation point in a mixed gas atmosphere consisting of ammonia, and endothermic gas. The resulting carbon and nitrogen react with the steel to carburise and nitride the components.

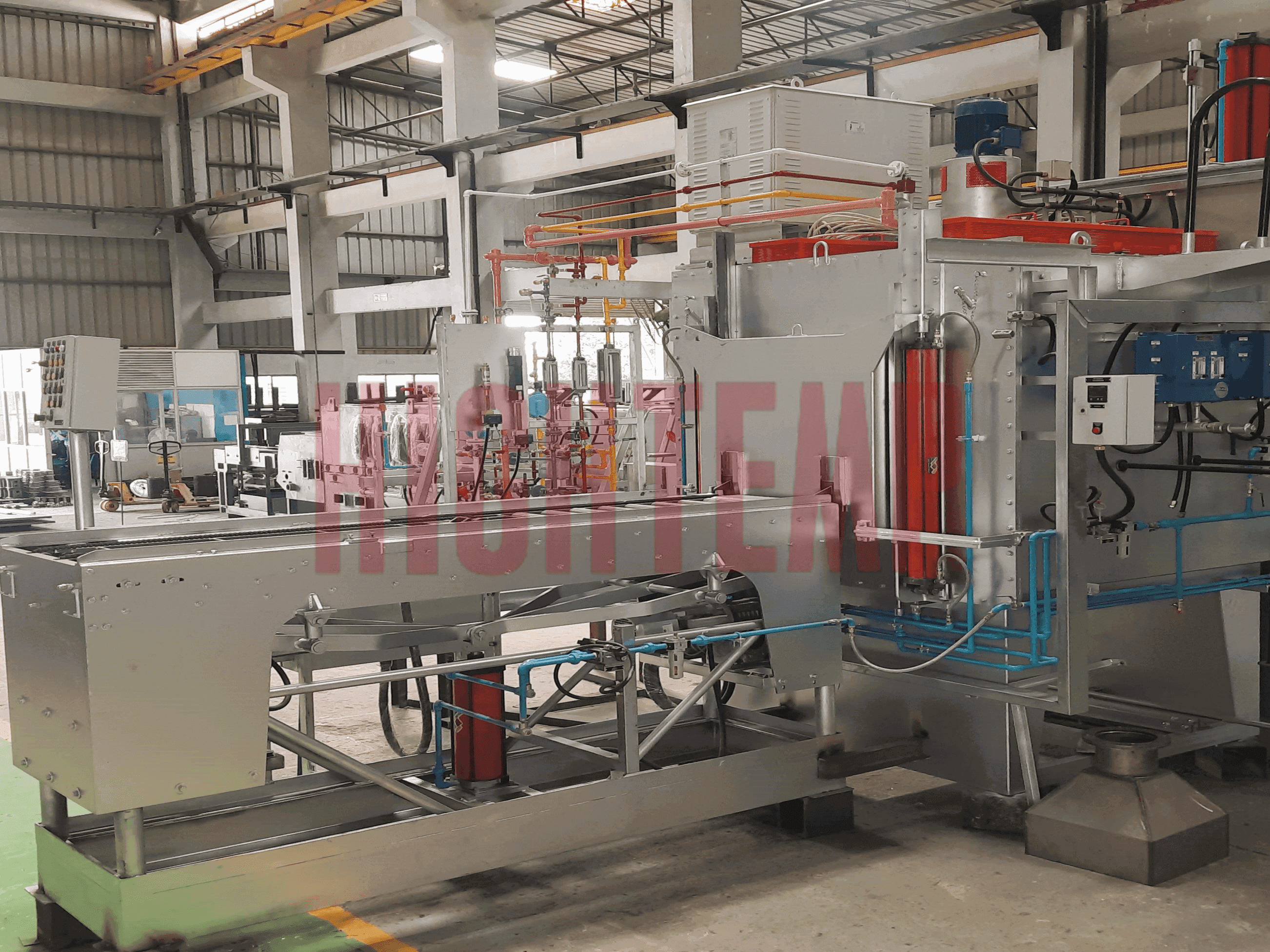

Integral Batch Sealed Quench Furnace

Sealed Quench Furnace (SQF) is used for high-precision heat treatment primarily in auto components industry. This allows heat treatment for carbon steel to reach the desired hardness and strength. The furnace feature allows the materials to be processed in batches rather than continuous operation. HIGHTEMP is the leading manufacturer of Sealed Quench Furnace in India that provides a global clientele, with sales volume exceeding 500+.