Blueing is a heat treatment process used primarily to enhance the corrosion resistance and appearance of steel components. It imparts a blue or blue-black finish to the steel surface through a controlled oxidation process. Additionally, the process offers some degree of rust resistance, surface hardness, uniform finish, and improved wear resistance.

Industries Served:

Auto components Industry

Aluminium Industry

Bearing Industry

Casting Industry

Material Grades That Can Undergo The

Blueing

Material

High-carbon Steel, Alloy Steels, Carbon Steels

Material Grade

M2, AISI 4340, 300M, 1045, 1075

Blueing Furnaces

Pit Type Furnace

Pit Furnace, also known as Pit-type Furnace, is an Industrial furnace used for heat treatment processes such as annealing, tempering, and hardening. The Pit Furnace is designed as a deep vertical cylindrical or rectangular chamber which can accommodate various sizes and shapes of materials. HIGHTEMP’s Pit Furnace is typically installed in a pit or deep chamber either below ground level or at ground level, which allows for easy loading and unloading of components.

Batch Furnace

HIGHTEMP offers advanced Batch Furnace solutions, designed to meet the specific heat treatment needs of various industries. Our Batch Furnaces provide reliable and uniform heat treatment for a range of materials, ensuring superior quality and durability. Our models include Roller Driven Batch Furnace, Two Tray Roller Hearth Carburising and Hardening Furnace, and Carburising and Hardening Furnace, offering flexibility and optimal performance.

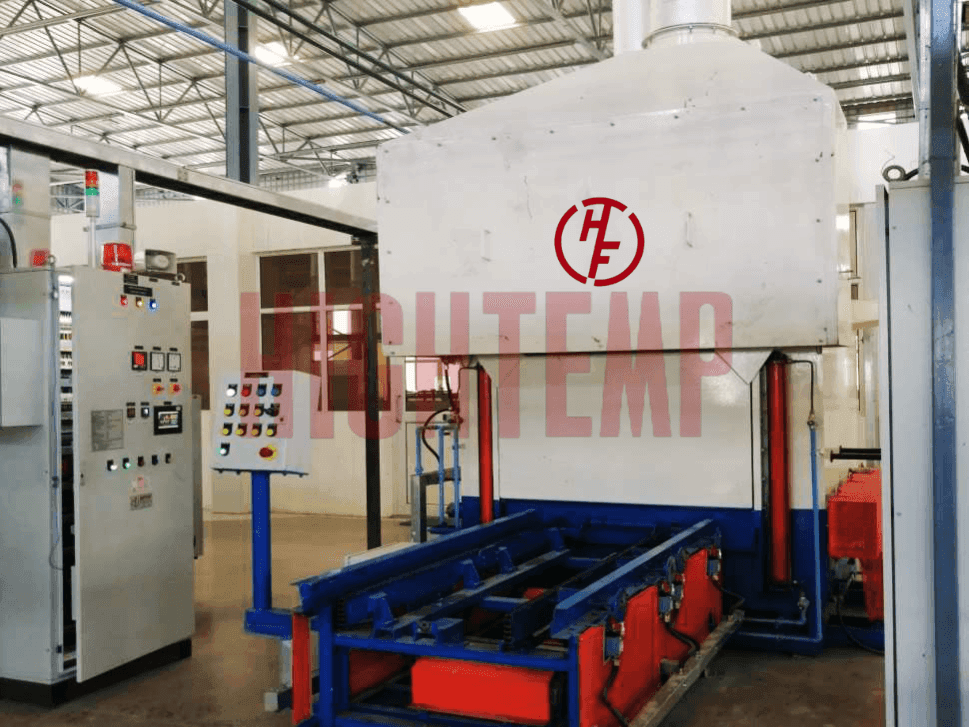

Blueing Furnace

Our Blueing Furnaces are designed to provide a protective, corrosion-resistant oxide layer on steel components by heating them to temperatures between 250°C to 350°C in a controlled atmosphere, followed by a chemical treatment to create a uniform, visually appealing finish, making them ideal for enhancing the durability and aesthetic appeal of components in industries such as automotive (brake components, gears, exhaust parts), aerospace (fasteners, bolts, shafts), and general manufacturing (tools, machine parts), with materials ranging from carbon steels to alloy steels and stainless steels, all while offering excellent corrosion resistance, increased wear resistance, and a consistent, high-quality finish for large-scale production.