- Superior Surface Hardening: The carburising process creates a wear-resistant surface that enhances the durability of components.

- Balanced Mechanical Properties: Tempering relieves internal stresses and improves toughness, ensuring components withstand high stress and impact.

- Wide Material Compatibility: Processes a broad range of steels, catering to diverse industrial needs.

- High Productivity: Semi-continuous operation allows for efficient treatment of multiple components with minimal downtime.

- Precision Control: Maintains a consistent carbon-rich atmosphere and precise temperature settings for uniform and reliable results.

- Extended Component Life: Improves fatigue strength and wear resistance, ensuring longer service life for treated parts.

- Energy Efficiency: Designed to optimize energy usage, reducing operational costs while maintaining high performance.

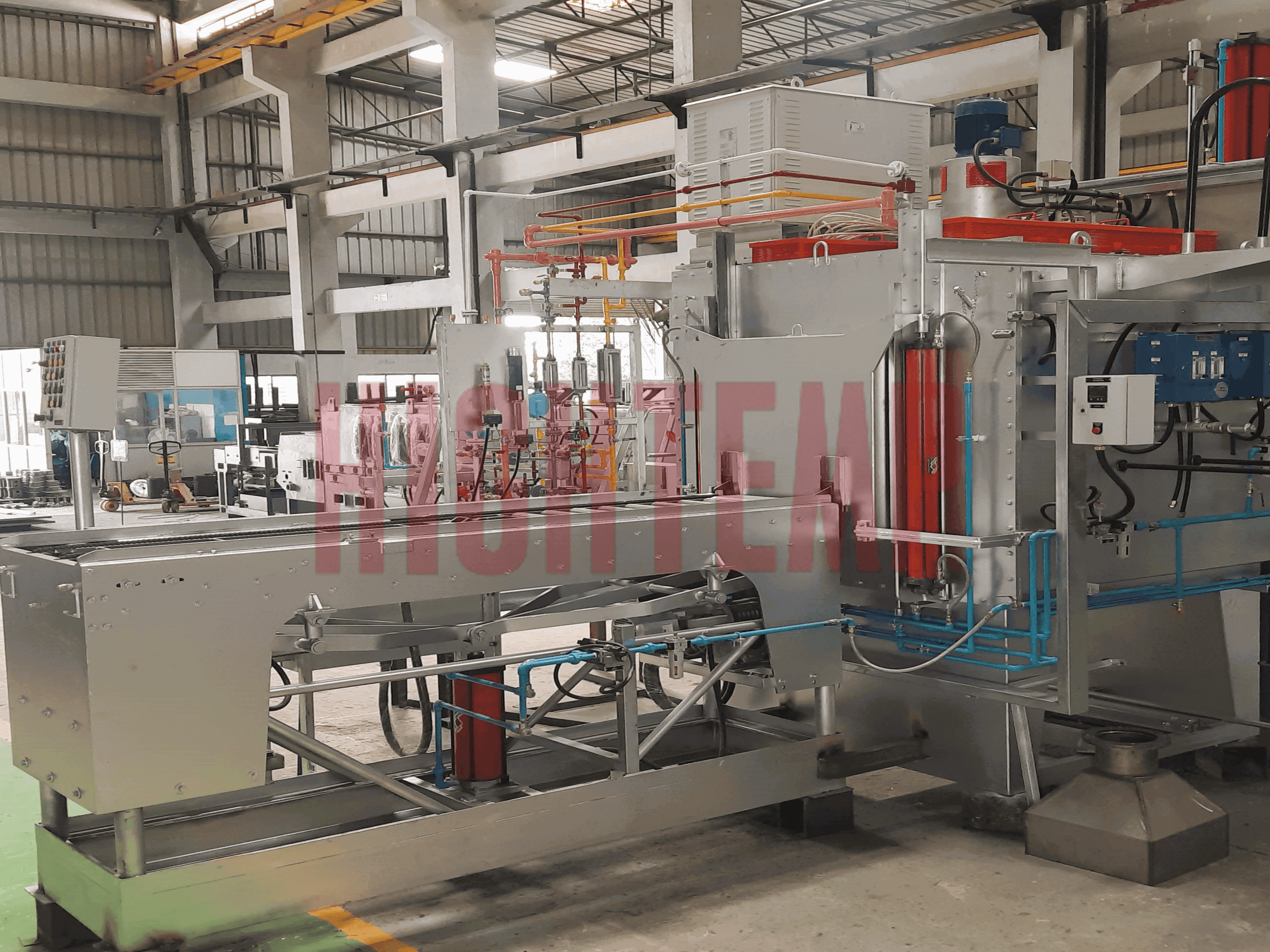

The Semi-Continuous Sealed Quench Furnace by HIGHTEMP provides an advanced heat treatment solution for carbonitriding/carburising and tempering, designed to enhance the wear resistance, surface hardness, and toughness of critical components such as gears, shafts, crankshafts, pins, bolts, fasteners, and bearings, and is compatible with a variety of material grades, including Medium- Carbon Steels like EN8, EN9, Alloy Steels such as EN19, EN24, SAE 4140, Low-Alloy Steels like 16MnCr5, 20MnCr5, SAE 8620, and High-Carbon Steels like EN31, making it the ideal choice for industries such as automotive, aerospace, heavy machinery, and precision engineering, where superior performance, durability, and reliability are crucial for high-stress, high-performance applications.

Our Sealed Quench Furnace is ideal for the heat treatment of components like gears, shafts, crankshafts, pins, bolts, fasteners, and tool & die parts. It offers a controlled environment for carburising processes, which are critical for enhancing the mechanical properties of materials such as EN8, EN9, EN19, EN24, 16MnCr5, 20MnCr5, SAE 8620, and EN31. Carburising is used to add carbon to the surface of low-carbon steels to enhance their hardness and wear resistance, while keeping the core material tough and ductile. After carburising, tempering is performed to reduce brittleness and improve the toughness of the hardened surface. It also helps relieve internal stresses that may result from the quenching process. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, austempering, neutral hardening, annealing, and bright hardening.

HIGHTEMP Sealed Quench Furnace is the ideal solution for the carbonitriding and tempering of high-performance components, ensuring enhanced surface hardness, wear resistance, and toughness. This furnace is particularly effective for components such as gears, shafts, pins, bolts, fasteners, crankshafts, tool & die parts, and bearings. Using materials like EN8, EN9, EN19, EN24, 16MnCr5, 20MnCr5, SAE 8620, and EN31 (high-carbon steels), it ensures consistent, superior-quality heat treatment. Carbonitriding is a surface hardening process where carbon and nitrogen are diffused into the steel surface, improving its hardness, wear resistance, and fatigue strength. The sealed quench furnace ensures a controlled atmosphere to minimize oxidation and decarburisation. After carbonitriding, tempering is used to relieve internal stresses and reduce brittleness while retaining the hardness of the treated surface. This furnace can perform other heat treatment processes, including carburizing, hardening, normalizing, nitrocarburizing, nitriding, austempering, neutral hardening, annealing, and bright hardening.