- The rotating hearth ensures even heat distribution across the workpieces, reducing temperature gradients and ensuring consistent results during the quenching process.

- The furnace optimizes heating for effective press quenching, enhancing hardness, strength, and toughness of the treated components.

- Suitable for various materials like steel, aluminum, and alloys, making it a versatile solution for different reheating and press quenching applications across industries.

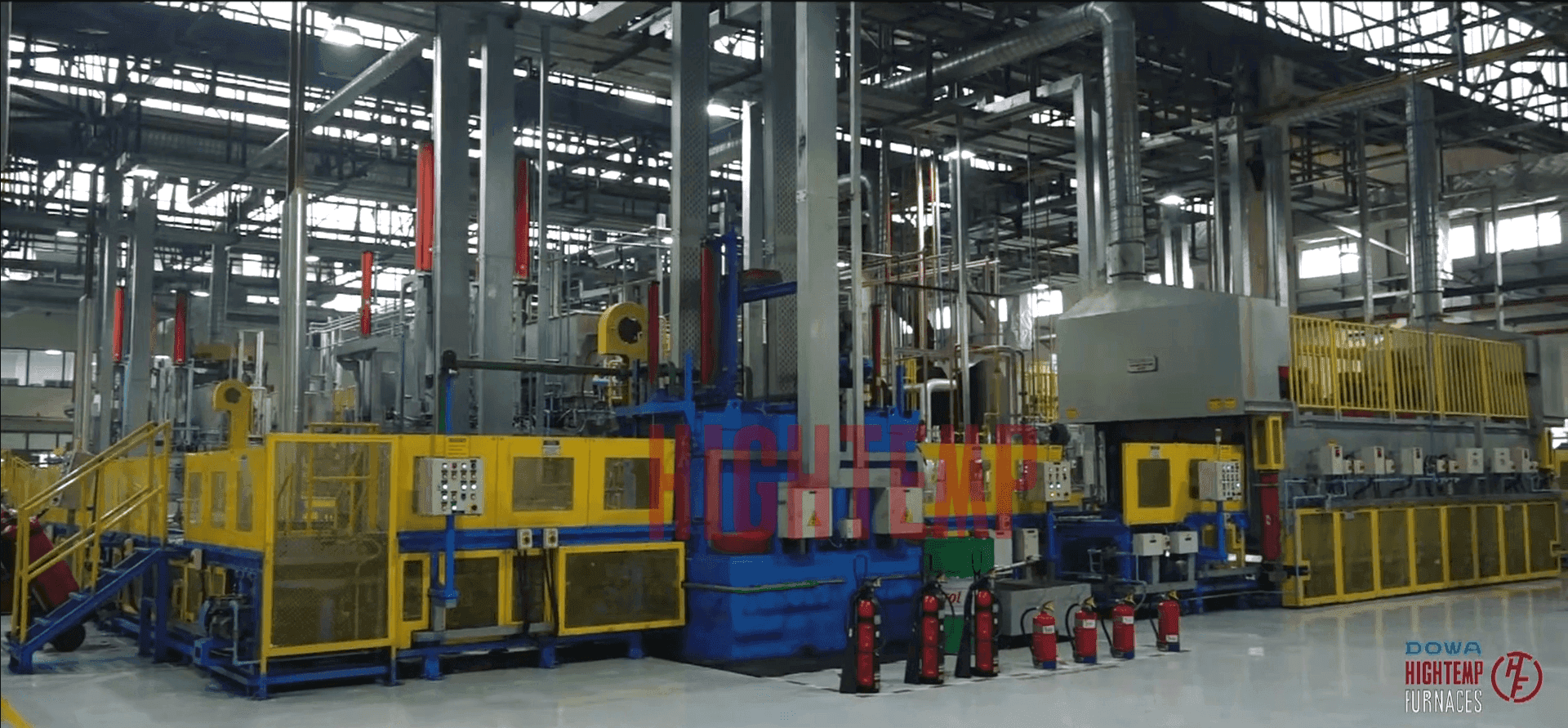

The HIGHTEMP Carburising and Hardening Furnace is an advanced industrial furnace specifically engineered to enhance the surface hardness and wear resistance of metal components. It utilizes a combination of carburising, where carbon is diffused into the surface layer of the metal in a precisely controlled atmosphere to significantly increase its hardness, and hardening, which involves uniform heating to a high temperature followed by rapid quenching. This process locks in the hard surface layer while maintaining a tough and ductile core. It is an indispensable tool for critical applications in various sectors such as automotive, aerospace, and industrial machinery, where components must possess exceptional durability and performance to withstand extreme conditions and high-stress environments.

The HIGHTEMP Continuous Gas Carburising Furnace is an advanced heat treatment solution designed for high-volume production and precise carburising of components. Built for efficiency and consistency, this furnace uses a continuous single-track design, making it ideal for industries that demand superior quality, cost-effective operations, and high throughput. Operating at temperatures of up to 950°C, the furnace introduces carbon into the surface layer of steel components to improve hardness, wear resistance, and fatigue strength, while maintaining a tough core. With options for endothermic gas or nitrogen-methanol atmospheres, it ensures optimal carburising conditions tailored to specific requirements.

The Continuous Mesh Belt Hardening Furnace from HIGHTEMP is a highly efficient and versatile heat treatment solution designed for the continuous processing of steel components, featuring a durable mesh belt for smooth transportation, multiple heating zones for precise temperature control, a quenching station for rapid cooling to achieve superior hardness and wear resistance, an advanced control system for real-time monitoring and regulation of key parameters such as temperature, atmosphere, and conveyor speed, and the ability to process a wide range of materials including low-carbon steels, medium-carbon steels, alloy steels, high-carbon steels, and stainless steels, making it ideal for high-volume production in industries such as automotive, aerospace, machinery, and tooling, where consistent quality, improved product performance, and energy efficiency are essential.