- Maintains a stable gas environment to avoid oxidation and ensure quality surface properties.

- Configurable to suit specific production requirements, including size, automation, and gas flow control.

- Durable construction with minimal maintenance requirements for continuous operation.

- Advanced insulation and heating systems reduce energy consumption and operating costs.

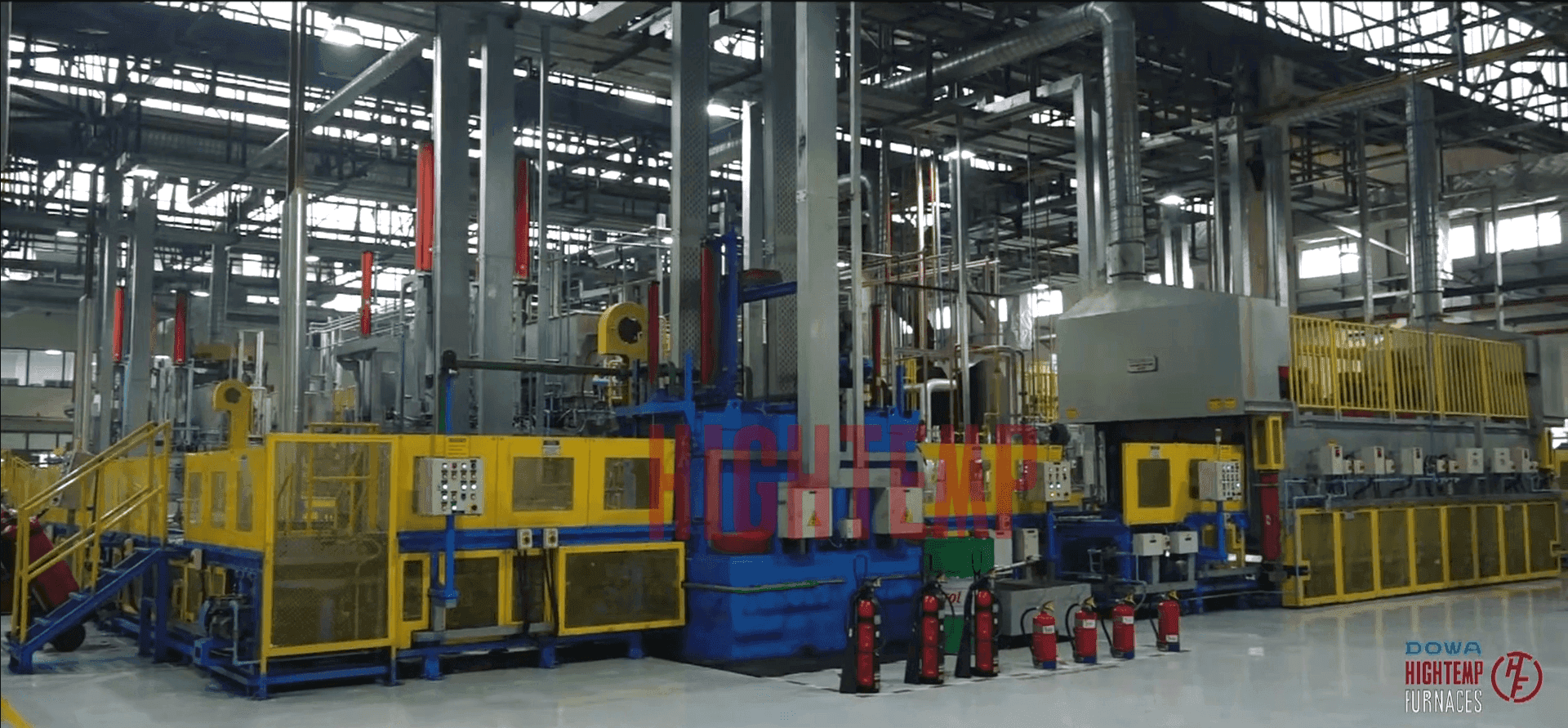

The HIGHTEMP Continuous Gas Carburising Furnace is an advanced heat treatment solution designed for high-volume production and precise carburising of components. Built for efficiency and consistency, this furnace uses a continuous single-track design, making it ideal for industries that demand superior quality, cost-effective operations, and high throughput. Operating at temperatures of up to 950°C, the furnace introduces carbon into the surface layer of steel components to improve hardness, wear resistance, and fatigue strength, while maintaining a tough core. With options for endothermic gas or nitrogen-methanol atmospheres, it ensures optimal carburising conditions tailored to specific requirements.

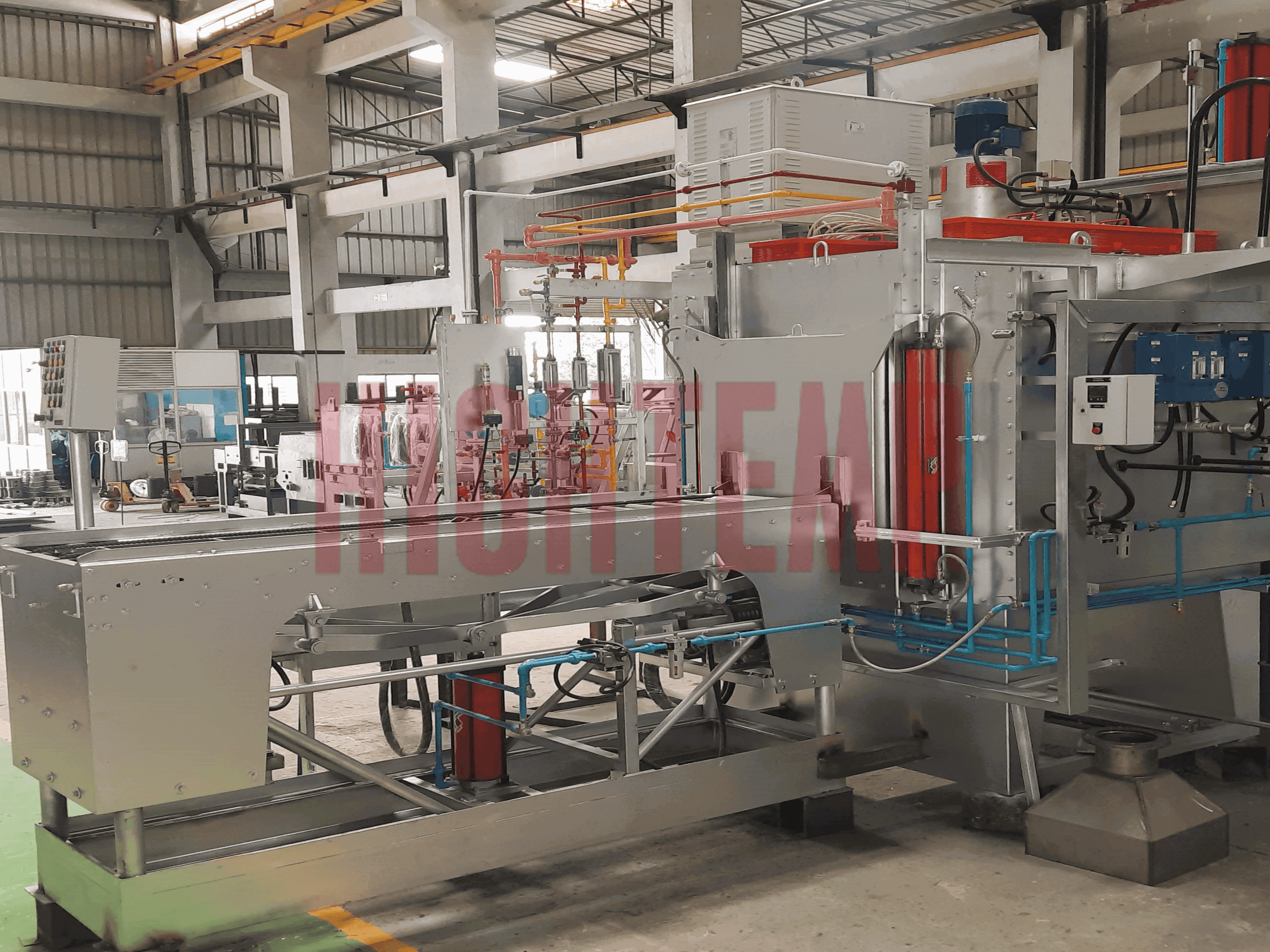

The Sealed Quench Furnace is a high-performance heat treatment system designed for austempering, carburising, and tempering. Ideal for components like gears, shafts, clutch plates, springs, fasteners, and crankshafts, it delivers superior wear resistance, toughness, and fatigue strength. Austempering is a specialized process that transforms steel into an ausferrite microstructure, enhancing toughness, wear resistance, and fatigue strength with minimal distortion. This makes it ideal for components that require superior mechanical performance. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, neutral hardening, annealing, and bright hardening.

Our Sealed Quench Furnace is ideal for the heat treatment of components like gears, shafts, crankshafts, pins, bolts, fasteners, and tool & die parts. It offers a controlled environment for carburising processes, which are critical for enhancing the mechanical properties of materials such as EN8, EN9, EN19, EN24, 16MnCr5, 20MnCr5, SAE 8620, and EN31. Carburising is used to add carbon to the surface of low-carbon steels to enhance their hardness and wear resistance, while keeping the core material tough and ductile. After carburising, tempering is performed to reduce brittleness and improve the toughness of the hardened surface. It also helps relieve internal stresses that may result from the quenching process. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, austempering, neutral hardening, annealing, and bright hardening.