- Carburising increases surface hardness for wear resistance.

- Treated components exhibit higher resistance to wear, fatigue, and impact, ensuring a longer service life.

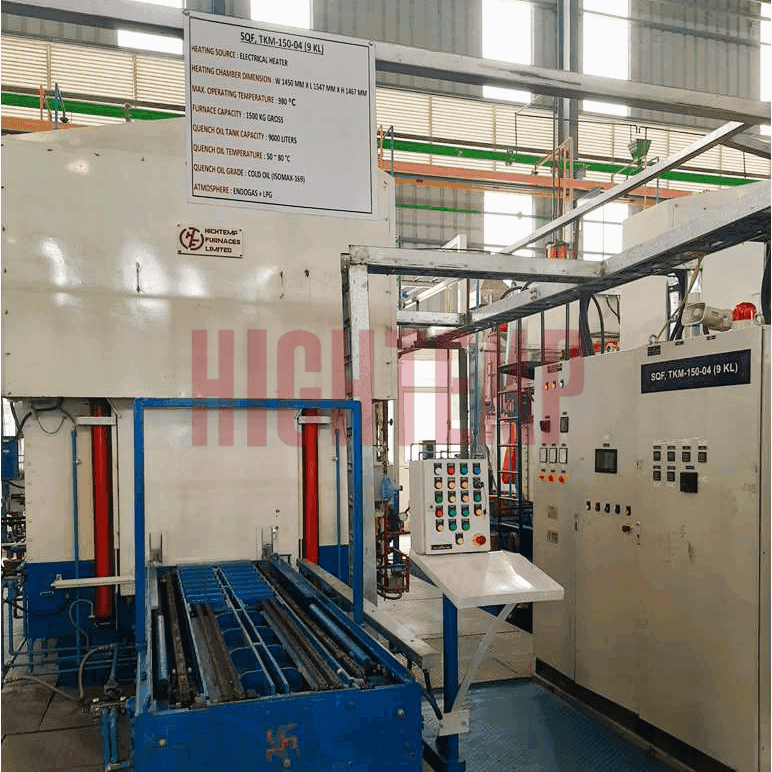

The Sealed Quench Furnace is a high-performance heat treatment system designed for austempering, carburising, and tempering. Ideal for components like gears, shafts, clutch plates, springs, fasteners, and crankshafts, it delivers superior wear resistance, toughness, and fatigue strength. Austempering is a specialized process that transforms steel into an ausferrite microstructure, enhancing toughness, wear resistance, and fatigue strength with minimal distortion. This makes it ideal for components that require superior mechanical performance. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, neutral hardening, annealing, and bright hardening.

The Sealed Quench Furnace is compatible for heat treatment of material grades like EN8, EN9, EN31, 16MnCr5, 20MnCr5, SAE 4140, and SAE 8620. This furnace ensures precise atmosphere control and uniform heating for consistent results. Whether strengthening automotive gears or hardening industrial tools, it excels in enhancing mechanical properties while minimizing distortion. In this Tempering is a crucial step that follows processes like carburising or case hardening, designed to relieve internal stresses, reduce brittleness, and enhance the overall toughness of components. Similarly, Austempering process ensures an optimal balance between hardness and ductility, making treated parts more durable and resistant to impact. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, austempering, neutral hardening, annealing, and bright hardening.

The Semi-Continuous Sealed Quench Furnace by HIGHTEMP provides an advanced heat treatment solution for carbonitriding/carburising and tempering, designed to enhance the wear resistance, surface hardness, and toughness of critical components such as gears, shafts, crankshafts, pins, bolts, fasteners, and bearings, and is compatible with a variety of material grades, including Medium- Carbon Steels like EN8, EN9, Alloy Steels such as EN19, EN24, SAE 4140, Low-Alloy Steels like 16MnCr5, 20MnCr5, SAE 8620, and High-Carbon Steels like EN31, making it the ideal choice for industries such as automotive, aerospace, heavy machinery, and precision engineering, where superior performance, durability, and reliability are crucial for high-stress, high-performance applications.