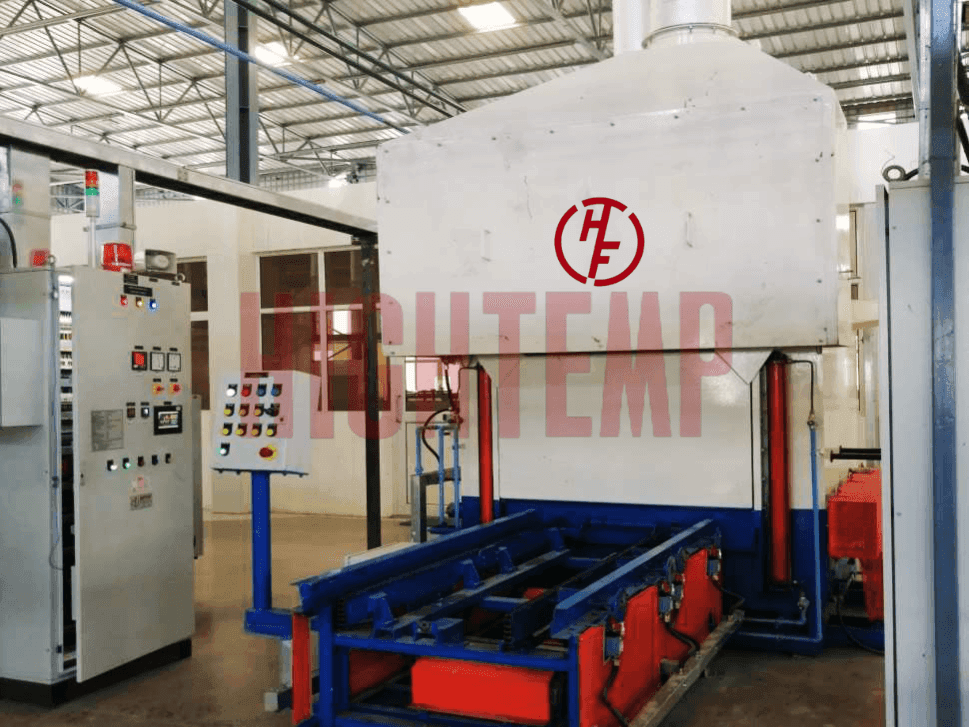

Sealed Quench Furnace (SQF) is used for high-precision heat treatment primarily in auto components industry. This allows heat treatment for carbon steel to reach the desired hardness and strength. The furnace feature allows the materials to be processed in batches rather than continuous operation. HIGHTEMP is the leading manufacturer of Sealed Quench Furnace in India that provides a global clientele, with sales volume exceeding 500+.

Safety

Quality Tested

Automation

Models Available

Specifications

Batch-type Integral Sealed Quench Furnace provides uniform heating through the closed pitch radiant tubes that are placed on either sides from the top. Radiant tubes are available in both Electric and Gas fired.

Includes Cast integral fan for the uniformity of the temperature and atmosphere.

Heat-resistant T-rails or Silicon Carbide Skids

Pneumatically operated doors and elevators

Integrated and compact layout with washing, tempering, and material handling equipment.

Availability of low-cost spares

All alarms and annunciations are provided with interlocks for safety

Turnkey project offered with process knowhow

Controls include options such as SCADA, Data Acquisition, and Furnace 4.0 (Industry IoT 4.0)

An automated control system includes-

- 1. PLC, carbon potential controlled with proportional valve.

- 2. Multi-point temperature recorder.

- 3. Thyristor with PID temperature control.

- 4. Touch screen graphic operator panel with alarm annunciation.

The furnace design is straight-through

Atmosphere Options include-

- 1. Endothermic gas

- 2. Nitrogen-Methanol

- 3. Fine Carburising Process Atmosphere

Design facilitates minimum downtime for maintenance or replacement

The operating temperature ranges between 800 to 970ºC.

Types

Electrically Heated

The Electric option for the SQF uses electrically heated elements instead of gas burners to alter the physical and mechanical properties of pieces. The heating element material are chosen to withstand high temperatures while ensuring uniform heating throughout the furnace. It is a good option in areas where electricity rates are economical. The Electrically heated SQF is preferred in industrial areas where precise temperature control and uniformity are critical.

Advantages

Controlled Atmosphere

The sealed environment of HIGHTEMP’s Batch type Integral Sealed Quench Furnace prevents oxidation, decarburisation, etc. Additionally, the sealed condition allows for precise control of the atmosphere to suit various heat treatment processes such as carburising, carbonitriding, annealing, etc.

Integral Quenching

HIGHTEMP’s SQF includes an integrated quenching chamber where the parts can be rapidly cooled. Integrating the heating and quenching within the unit is space-efficient as it reduces the need for additional tanks.

Batch processing

HIGHTEMP’s fully automated furnace setup including preheating, pre cum post washing, and tempering furnace helps in achieving both the minimum and maximum batch capacities.

Uniform Heating

The design of the furnace ensures even heat distribution throughout the chamber, ensuring consistent hardness across the batch of pieces.

Seamless Automation

Automated control for alarms, temperature control, and temperature recorders help improve efficiency and reduce labour costs.

Energy Efficiency

The Sealed design minimises heat loss, making the Sealed Quench Furnace more energy efficient.

Industries Served

Auto components Industry

HIGHTEMP’s Sealed Quench Furnace is used in the Auto components Industry to treat various parts in order to enhance the mechanical properties and performance of the parts. The SQF can help with consistent quenching, and uniform cooling while reducing the risks of oxidation of parts where performance and hardness of the parts are critical.

Material Grades Available

- Carbon Steel - 1020, 1040, 1060

- Alloy Steel - 4140, 4340, 8620

- Tool Steel - A2, D2, M2, O1

Parts

Planetary Gears, Axle Shafts, Valves, Arm Lever, Pins, Brake web, Bevel Gears, Wheel rims, U-Joints, Engine, Friction plates

Applications

Why Choose Hightemp

HIGHTEMP, a subsidiary of DOWA Thermotech Co. Limited is India’s No 1 manufacturer of Heat Treatment Furnaces selling over 1700 globally, and 500 Sealed Quench Furnaces.

HIGHTEMP is equipped with technology such as SCADA, and FURNACE 4.0 (IoT-enabled Furnaces), remote access to process data on HIGHTEMP’s equipment.

Safety features such as high-pressure safety valve, over-temperature safety protector, audio-visual indication, and alarms comes as a basic requirement of all furnaces.

Oxygen Probe Control System includes carbon potential controller and actuator motor with valve.

HIGHTEMP offers cost-effective SQF without compromising on quality and industry requirements.

Our Clients

Are you interested in our

Integral Batch Sealed Quench Furnace ?

Please, read the answers to frequently asked questions about our products.

Sealed Quench Furnace is used for a heat treatment process that requires rapid cooling of metal parts to achieve the desired mechanical properties such as strength or hardness under protective atmosphere. There are two important steps to this process- heating the metal to a high temperature which is followed by quickly cooling under protective atmosphere to avoid scaling.

Sealed Quenching prevents oxidation and minimizes distortion of the parts. Additionally, rapid cooling helps achieve the desired hardness and mechanical properties of the parts as per industry standards.

HIGHTEMP’s Sealed Quench Furnace’s heating process can range from 800ºC to 1200ºC. The rate of heating of the SQF is about 4 hours from room temperature to 930ºC under No Load.

Quenching mediums such as Cold quenching oils, Hot Quenching oils, Polymers, and Salts can be used for the Sealed Quench Furnace.