Endo Gas Generator, also known as Endothermic Gas Generator, is a machine used to create an atmosphere to provide positive pressure in a heat-treating furnace, and a platform to formulate the carburising environment. Endo gas is commonly used in various industrial processes, particularly in the heat treatment of metals.

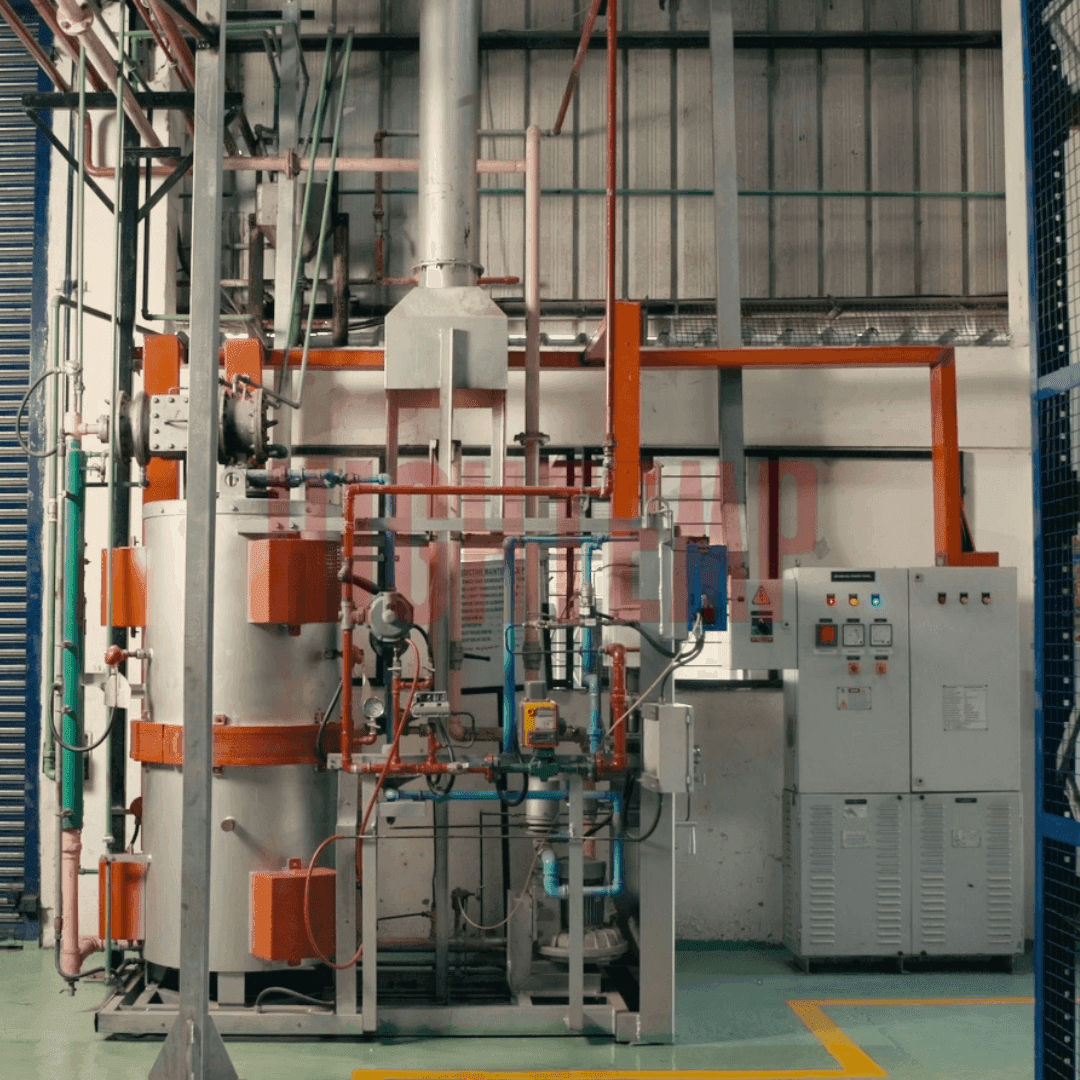

HIGHTEMP’s Endo Gas Generator offers a unique soot-free control system with an excellent reputation for trouble-free operation.

Safety

Quality Tested

Automation

Models Available

Specifications

Double pass retort with a uniform heating mechanism with a patented pulse-less blower to ensure a constant and stable supply of output carrier gas.

Includes emergency shut-off valve, pressure switch, and fire check valve.

Interlocks are provided for all alarms and annunciation to ensure safe operation.

Fully automated PID Controls and zero-balance regulators and carburettor are included.

Option for carbon potential control with Lambda probe is provided.

High-efficiency insulation for lower skin temperature.

Overheat alarms, and gas failure alarms are provided.

Capacity of models using Butane/ Propane as the base gas are- a. SF 500 EN (14m3/hr) b. SF 1000 EN (28m3/hr) c. SF 2000 EN (56m3/hr) d. SF 4000 EN (113m3/hr)

Power Panel contains all electrical switch gear items such as MCCB, MCB, OLR, Push buttons, and ON/OFF switches.

Advantages

Consistent Gas Composition

The Endo Gas Generator produces a consistent and controlled gas composition which is essential for the heat treatment process. This allows for a specific atmosphere to prevent oxidation and ensure high-quality results.

Controlled Reaction

The Endo Gas Generator provides a stable environment for chemical reactions, improving the efficiency and outcomes of the components.

Good Long-term Investment

HIGHTEMP’s Endo Gas Generator offers a good return on investment by improving process efficiency and product quality over the long term.

Soot-Free Control System

HIGHTEMP’s Endo Gas Generator offers a unique feature- a soot-free control system ensuring a trouble-free operation while reducing the risk of soot deposition on treated components.

Adjustable Gas Composition

The gas mixture can be adjusted to meet specific requirements, allowing the industry to customize based on the needs of the different applications.

Industries Served

Auto components Industry

Endo Gas Generators are useful in the automotive industry, especially for their role in processes like heat treatment and surface hardening. Endo Gas creates a controlled atmosphere that prevents oxidation of components during the heat treatment process.

Material Grades Available

- Carbon Steel - 1045, 1060

- Alloy Steel - 4140, 4340

- Case-Hardened Steel - 8620, 9310

Parts

Shafts, Bearings, Cranks, Camshafts, Pistons, Connecting Rods, Shock Absorber Rods, Brake Calipers

Why Choose Hightemp

HIGHTEMP is India’s No 1 manufacturer of Heat Treatment Furnaces and Commercial Heat Treatment.

HIGHTEMP ensures a soot-free heat treatment with the Endo Gas Generator.

Safety features include a temperature controller, emergency shut-off valve and pressure switches, which are interconnected.

Lambda probe is given to control the dew point in the gas generator.

HIGHTEMP offers cost-effective Endo Gas Generator which meets the industry standards.

Our Clients

Are you interested in our

Endo Gas Generators ?

Please, read the answers to frequently asked questions about our products.

Endo Gas is generated when the natural gas is mixed with steam and is heated to high temperatures. This process triggers chemical reactions, and the gas obtained is purified and used for industrial applications such as heat treatment processes.

HIGHTEMP’s Endo Gas Generator is a machine that produces endo gas. It is commonly used to create a controlled atmosphere for industrial processes, such as heat treatment and metal hardening.

Endo gas can help improve metal properties (such as hardness and strength), reduce the process of oxidation, and provide consistent and reliable conditions.