- Multi-Zone Heating: Equipped with multiple heating zones for precise temperature profiling, ensuring optimal treatment across varying component sizes.

- Compact Footprint: Space-efficient design allows seamless integration into existing production facilities without requiring extensive modifications.

- Dual Atmosphere Options: Provides flexibility with endothermic gas or nitrogen-based atmospheres for enhanced control over heat treatment environments

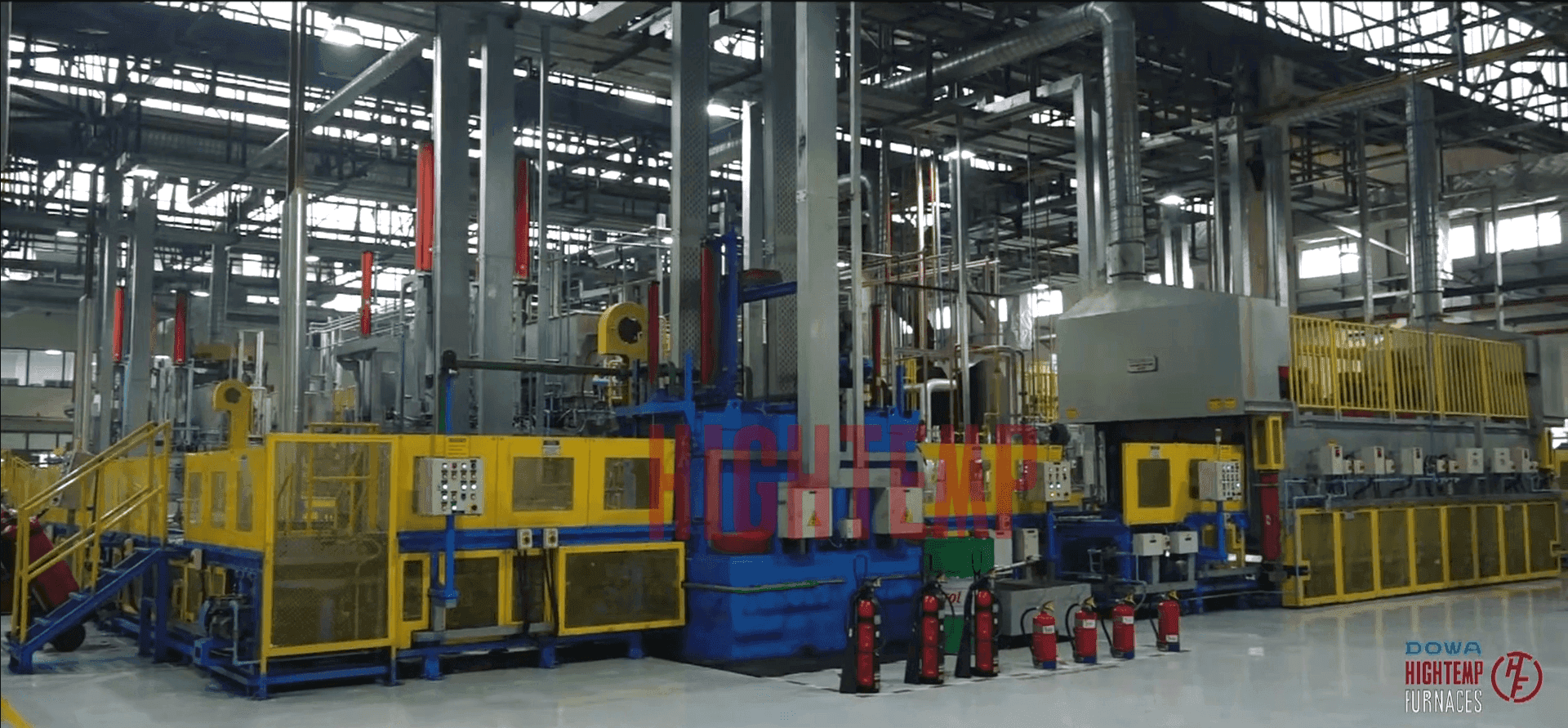

The HIGHTEMP Continuous Hardening and Tempering Furnace is a cutting-edge solution designed for high-volume heat treatment applications. Engineered to deliver precision, efficiency, and reliability, this furnace seamlessly integrates the hardening and tempering processes, meeting the demands of industries where consistent quality and performance are crucial. With a temperature range of 850°C to 1,100°C for hardening, the furnace ensures precise austenitization to achieve maximum hardness. For tempering, it operates between 150°C and 650°C, effectively relieving stresses and reducing brittleness to enhance toughness while maintaining strength.

The Continuous Mesh Belt Hardening Furnace from HIGHTEMP is a highly efficient and versatile heat treatment solution designed for the continuous processing of steel components, featuring a durable mesh belt for smooth transportation, multiple heating zones for precise temperature control, a quenching station for rapid cooling to achieve superior hardness and wear resistance, an advanced control system for real-time monitoring and regulation of key parameters such as temperature, atmosphere, and conveyor speed, and the ability to process a wide range of materials including low-carbon steels, medium-carbon steels, alloy steels, high-carbon steels, and stainless steels, making it ideal for high-volume production in industries such as automotive, aerospace, machinery, and tooling, where consistent quality, improved product performance, and energy efficiency are essential.

The Continuous Tempering Furnace is designed for efficient tempering of steel components at temperatures ranging from 190°C to 600°C, offering production capacities of 250 kg/hr to 1500 kg/hr and featuring a mesh belt conveyor system for uniform heat treatment, precise temperature control, energy efficiency, and automation, making it ideal for industries like automotive, aerospace, and manufacturing to process components such as gears, shafts, springs, and fasteners made from materials like carbon steel, alloy steel, tool steel, and spring steel, while ensuring improved mechanical properties, durability, and high productivity.