- A controlled atmosphere furnace minimizes the formation of scale, ensuring the surface remains free from contaminants.

- Prepares steel for plating or coating by ensuring better adhesion of the coating material to the substrate.

- By removing excess carbon, it reduces the risk of cracking during welding and other forming processes

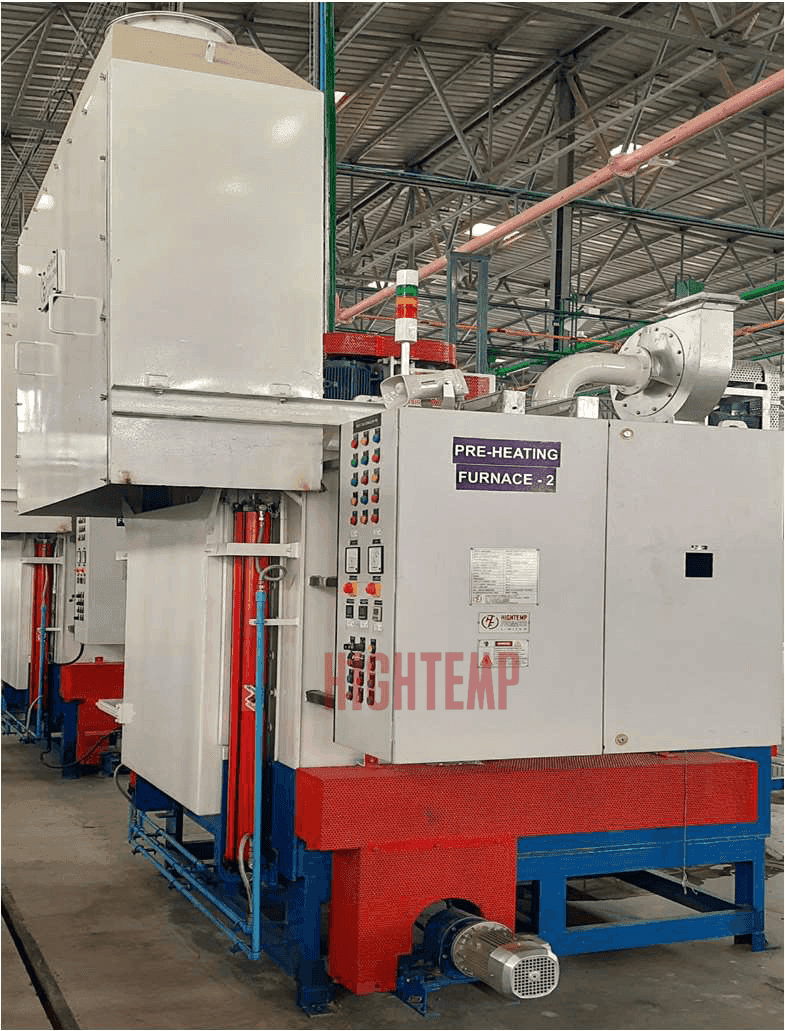

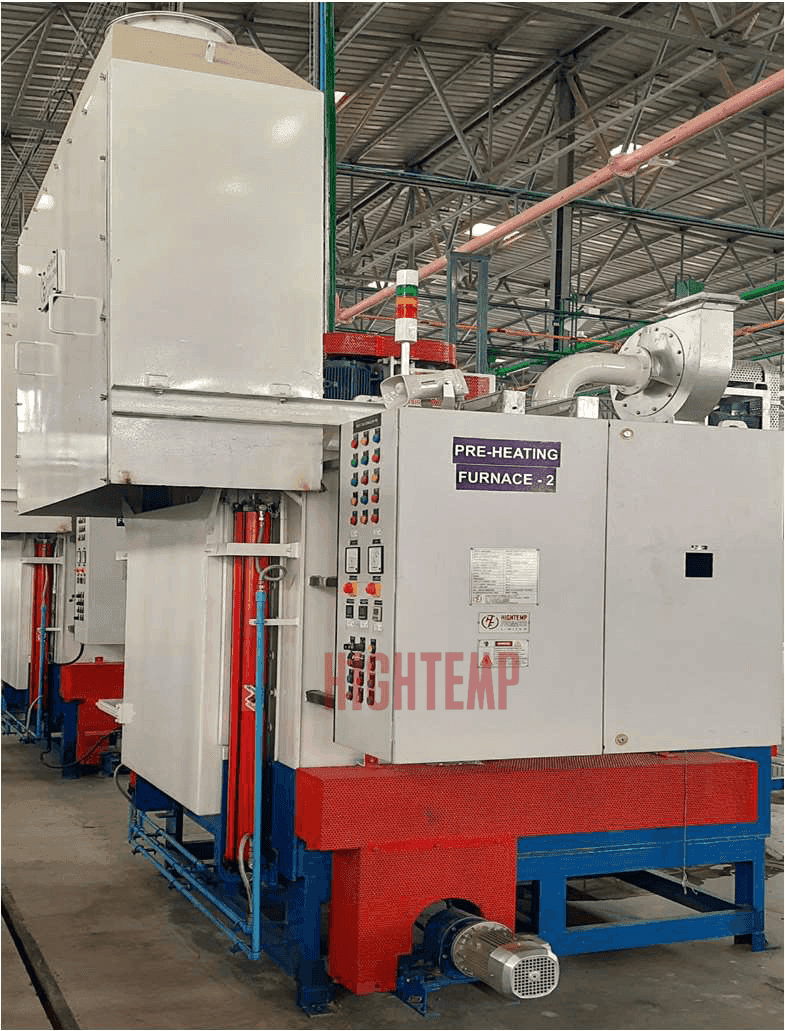

HIGHTEMP Decarb Annealing Furnaces operate in a controlled atmosphere (800°C to 950°C) using gases like hydrogen or carbon monoxide to reduce surface carbon, enhancing weldability, surface quality, and machinability. Ideal for automotive, aerospace, and manufacturing applications, these furnaces process components like exhaust valves, shafts, and gears before plating, coating, or welding, minimizing oxidation and scaling. With production rates ranging from 1 ton/day to 6 tons/day for batch-type and 500kg/hr to 2000kg/hr for continuous-type furnaces, we offer flexible solutions for various production needs.

At HIGHTEMP, our Isothermal Annealing Furnaces are engineered to process materials such as carbon steels (e.g., AISI 1040, 1050), alloy steels (e.g., 4140, 4340), cast iron (e.g., grey and ductile iron), and stainless steels (e.g., 304, 316) by heating them to temperatures between 700°C and 900°C, holding them at an isothermal phase to achieve uniform microstructures, and cooling them in a controlled manner. This process reduces hardness, enhances machinability, and improves mechanical properties for components such as gears, shafts, bearings, and engine blocks, meeting the high standards of the automotive, aerospace, and manufacturing industries.

Our Blueing Furnaces are designed to provide a protective, corrosion-resistant oxide layer on steel components by heating them to temperatures between 250°C to 350°C in a controlled atmosphere, followed by a chemical treatment to create a uniform, visually appealing finish, making them ideal for enhancing the durability and aesthetic appeal of components in industries such as automotive (brake components, gears, exhaust parts), aerospace (fasteners, bolts, shafts), and general manufacturing (tools, machine parts), with materials ranging from carbon steels to alloy steels and stainless steels, all while offering excellent corrosion resistance, increased wear resistance, and a consistent, high-quality finish for large-scale production.