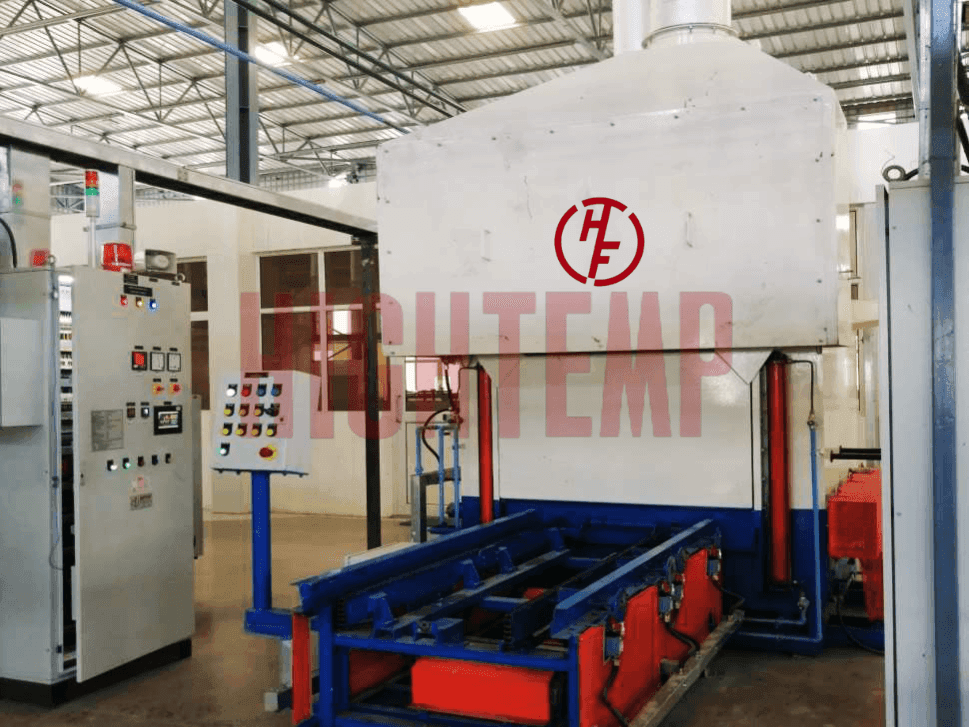

HIGHTEMP's Chamber Furnace is a reliable solution for batch heat treatment, offering excellent temperature uniformity and precise control. Its robust design ensures durability and consistent performance, making it suitable for various applications. The furnace is engineered for efficiency, delivering high-quality results with optimal energy usage.

Safety

Quality Tested

Automation

Models Available

Specifications

Operates efficiently up to 1000°C, suitable for a wide range of heat treatment applications.

High-performance, long-lasting elements for uniform temperature distribution.

Multi-layered ceramic fiber insulation minimizes heat loss and improves energy efficiency.

Customizable chamber sizes to accommodate small to large batch loads.

Advanced digital controllers ensure precise and consistent heating.

Durable, high-grade steel construction for long service life.

Optional gas flow systems for inert or controlled atmospheres.

Equipped with over-temperature protection and automated shut-off systems.

Types

Gas Fired

HIGHTEMP's Gas-Fired Chamber Furnace is a batch-type heat treatment system known for its energy efficiency and consistent performance. It utilizes gas burners to achieve rapid and uniform heating within a well-insulated chamber, reducing heat loss and operating costs. Designed for durability and precision, it ensures reliable temperature control and adaptability for various heat treatment requirements.

Advantages

Uniform Heating Performance

HIGHTEMP's Chamber Furnace ensures consistent temperature distribution throughout the chamber. This even heating is critical for achieving reliable results in heat treatment, thanks to strategically placed heating elements or gas burners that minimize temperature fluctuations.

Wide Temperature Range

Capable of operating at temperatures up to 1000°C, HIGHTEMP’s Chamber Furnace is suitable for various heat treatment processes. This versatility makes it ideal for both low and high-temperature applications, accommodating a wide range of materials.

Energy Efficiency

Featuring advanced insulation, the furnace minimizes heat loss, optimizing energy use and reducing operational costs. HIGHTEMP’s electrically heated models provide precise energy consumption, while gas-fired versions offer cost-effective and efficient heating.

Precise Temperature Control

Equipped with digital and programmable controllers, HIGHTEMP’s Chamber Furnace provides accurate and reliable temperature regulation. This ensures that materials are heated to the exact specifications, leading to improved quality and reduced variability in results.

Customizable Configurations

Available in various sizes and capacities, HIGHTEMP’s Chamber Furnace can be tailored to specific operational needs. Custom features, including automated loading systems, atmosphere control, and specialized insulation, make it adaptable for diverse applications.

Durable and Robust Construction

Built with high-quality materials, HIGHTEMP’s Chamber Furnace is designed to withstand high temperatures and heavy-duty use. The furnace’s rugged steel construction guarantees long-lasting performance, even in the most demanding industrial environments.

Flexibility in Heat Treatment Applications

HIGHTEMP’s Chamber Furnace is designed to handle a variety of heat treatment processes, from hardening and annealing to tempering and stress relieving. Its versatility allows it to accommodate different materials, including ferrous and non-ferrous metals, as well as advanced alloys.

Enhanced Safety Features

Safety is a top priority with HIGHTEMP’s Chamber Furnace. Equipped with features such as over-temperature protection, automatic shut-off systems, and door interlocks, it ensures a safe working environment and minimizes risks to both operators and equipment.

Low Maintenance Requirements

With a straightforward design and minimal moving parts, HIGHTEMP’s Chamber Furnace requires less maintenance. Easy access to components simplifies servicing, reducing downtime and enhancing productivity and reliability.

Environmentally Friendly Operation

HIGHTEMP’s electrically heated Chamber Furnace offers emission-free heating, making it an environmentally conscious choice. Gas-fired models are engineered for high combustion efficiency, helping to minimize emissions and comply with environmental standards.

Industries Served

Aerospace Industry

The aerospace industry demands the highest level of precision and performance, and HIGHTEMP’s Chamber Furnace plays a pivotal role in ensuring the strength, durability, and thermal stability of critical aerospace components. With the ability to handle materials that need to endure extreme temperatures, Chamber Furnace delivers consistent and uniform heating, improving the material properties of parts designed for high-stress environments.

Material Grades Available

- Titanium Alloys - Ti-6Al-4V, Ti-6Al-4V ELI

- Nickel Alloys - Inconel 625, Inconel 718, Inconel 625

- Stainless Steel - AISI 304, AISI 316, AISI 440C

- Steel Alloys - AISI 4340 , AISI 4140

- Maraging Steel - Maraging 300

- Aluminum Alloys - AA2024, AA7050, AA7075

Parts

Turbine blades, Landing gear, Engine parts, Wing structures

Applications

Why Choose Hightemp

Proven Expertise: Over a decade of experience in designing and manufacturing heat treatment furnaces.

State-of-the-Art Technology: Equipped with Industry 4.0 features like SCADA and data acquisition.

Custom Solutions: Tailored furnace designs to meet specific process requirements.

Cost-Effective: Energy-efficient designs with low operational costs.

Reliable Support: Comprehensive after-sales service and easy availability of spare parts.

Our Clients

Are you interested in our

Chamber Furnace ?

Please, read the answers to frequently asked questions about our products.

The furnace operates between 100°C and 1000°C, suitable for various heat treatment processes.

Yes, the furnace supports endothermic gas, nitrogen-methanol, and air atmospheres, depending on the application.

Automotive, aerospace, and heavy engineering industries commonly use it for precision heat treatments.

Integrated fans and radiant tube designs ensure even temperature distribution throughout the chamber.

Safety interlocks for overheating, alarms for gas leaks, and automated doors for secure operation.