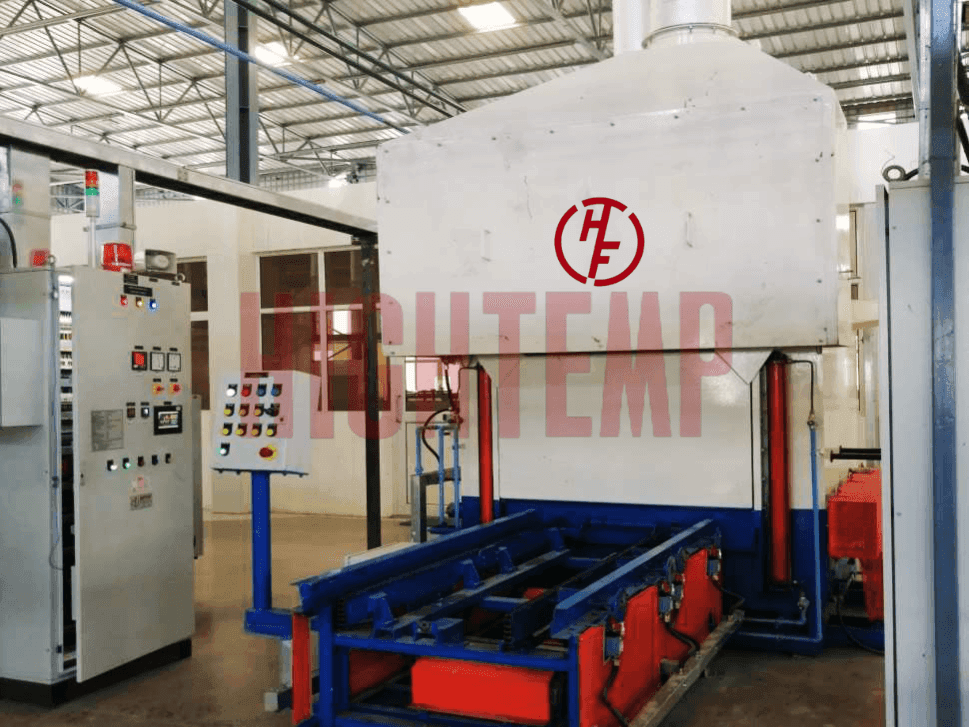

HIGHTEMP's Bogie Hearth Furnace is designed for the heat treatment of heavy and large components. Equipped with a bogie, the furnace simplifies the loading and unloading process, making it ideal for applications requiring precision and uniform heating. The insulation and efficient heating systems ensure energy savings while maintaining superior performance.

This furnaces can be customized with single or double doors and single or double bogies to meet specific user requirements. Materials are loaded onto the bogie using an EOT crane or mechanical devices, and the loaded bogie is moved into the furnace via an electro-mechanical rack-and-pinion or rope-and-drum bogie drive mechanism, ensuring smooth and efficient operation.

Safety

Quality Tested

Automation

Specifications

Operating temperature range: 500°C to 950°C

Advanced insulation for energy efficiency and minimal heat loss.

Equipped with single/double doors and single/double bogies for customization.

Optional intermediate door to divide the furnace into separate chambers.

Loading via EOT cranes or mechanical devices for safe and efficient handling.

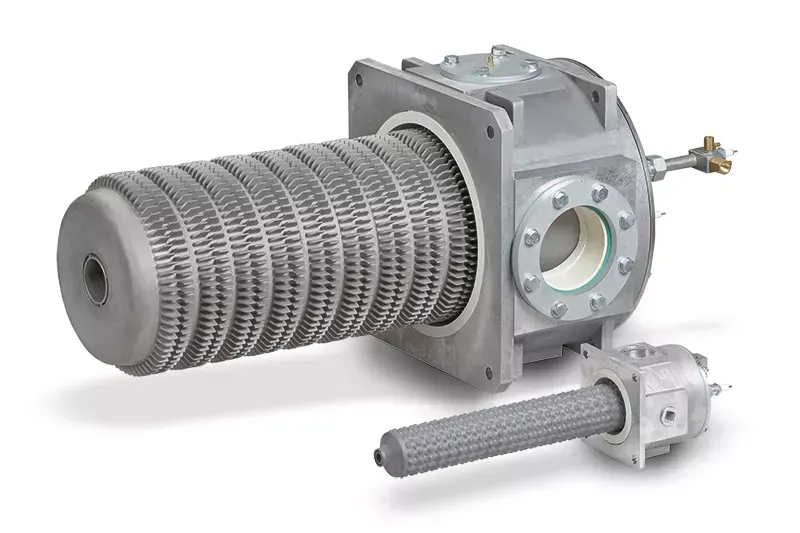

Electro-mechanical rack-and-pinion or rope-and-drum bogie drive mechanism.

Uniform temperature distribution with precision temperature controls.

Sturdy construction for durability and reliability in heavy-duty applications.

Designed for seamless integration with automated systems.

Types

Gas-Fired

Powered by advanced gas burners, this furnace offers rapid heating and cost-effective operation, making it ideal for high-volume industrial applications. Its uniform heat distribution ensures consistent results across the load.

Advantages

Accommodates large and heavy components.

Customizable design with one side loading and other side unloading.

Energy-efficient operation with advanced insulation.

Smooth loading and unloading with mechanized bogie systems.

Uniform heat distribution for consistent results.

Supports multiple heat treatment processes.

Rugged construction for long service life.

Flexible operation with optional intermediate door for chamber separation.

Minimal downtime with reliable automation and advanced technology.

Designed to meet diverse industrial standards and specifications.

Industries Served

Auto components Industry

HIGHTEMP’s Bogie Hearth Furnace is ideal for the automotive sector, enabling the heat treatment of heavy and intricate parts used in vehicles. Its robust design accommodates large-scale components, ensuring they achieve the necessary mechanical properties for safety and performance. With its customizable features and efficiency, the furnace supports high productivity in automotive manufacturing.

Material Grades Available

- carbon steels - 1010, 1018, 1035, 1040, 1045, 1060, 1065, 1070, 1080, 4140, 8620

- stainless steels - 410, 420, 409

Applications

Why Choose Hightemp

Customizable Solutions: Single/double doors, bogies, and intermediate chambers to meet diverse needs.

Advanced Technology: Precision temperature control and uniform heating for consistent results.

Robust Construction: Built for durability and reliability in heavy-duty applications.

Energy Efficiency: Advanced insulation and efficient heating systems reduce energy costs.

Comprehensive Service: Tailored design, installation, and after-sales support.

Proven Expertise: Decades of experience in manufacturing industrial heat treatment equipment.

Our Clients

Are you interested in our

Bogie Hearth Furnace ?

Please, read the answers to frequently asked questions about our products.

The bogie is transported using a rack-and-pinion or rope-and-drum drive mechanism.

A Bogie Hearth Furnace is used for heat treatment of large, heavy, or complex components across various industries, ensuring uniform heating and mechanical property enhancement.

The furnace can operate at temperatures up to 950°C, depending on the design and application.

The furnace can be customized with single/double doors, single/double bogies, intermediate doors to divide the chamber, and different heating mechanisms to suit specific requirements.