- Roller hearth technology ensures even heating across all parts.

- The two-tray design allows simultaneous batch processing, improving throughput.

- PLC-based systems ensure precise carburising depth and hardness levels.

- Efficient use of process gases like endothermic gas or nitrogen reduces operating costs.

- Available with electric or gas-fired heating to suit production requirements.

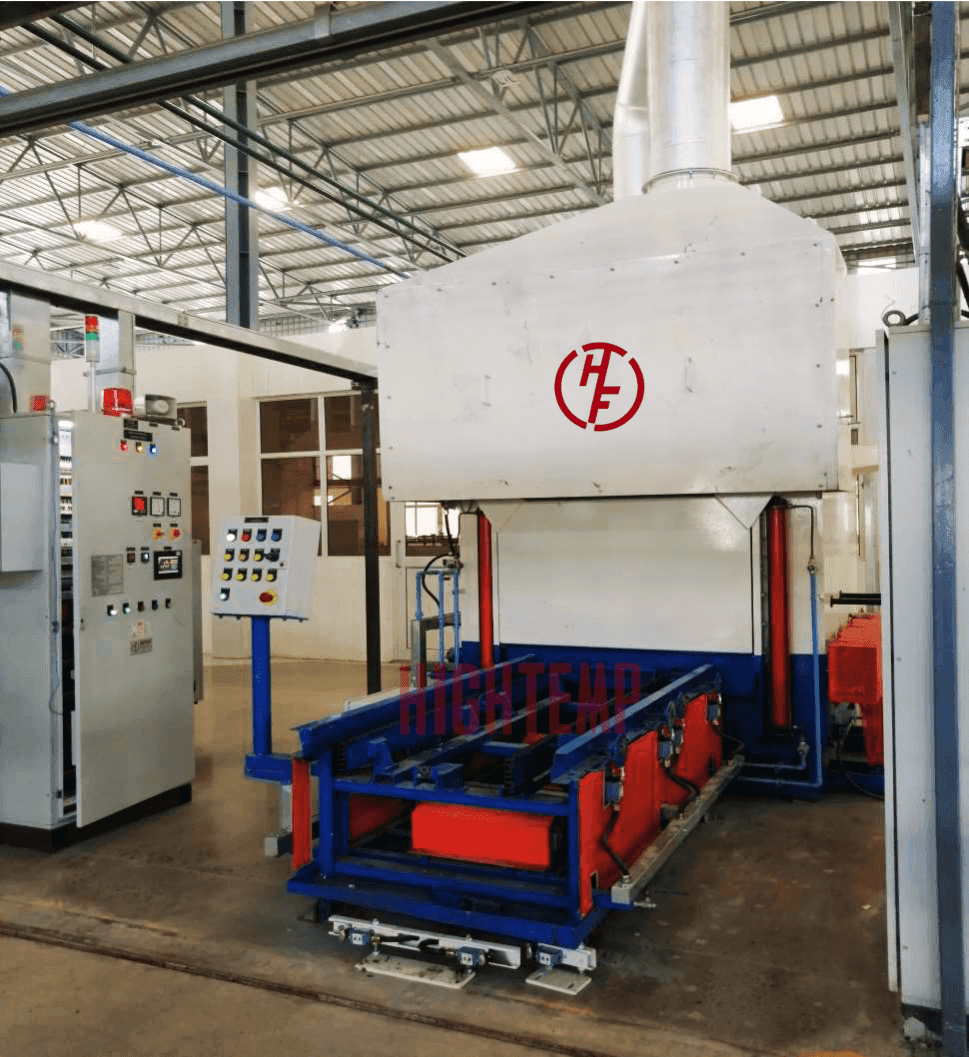

HIGHTEMPs Tempering Furnaces is a Chamber Furnace designed for operating at temperatures ranging from 100°C to 650°C to achieve desired mechanical properties. It also features production capacities ranging from 200 kg to 2500 kg gross per batch. The heating and circulation system ensures uniform heat distribution, for every steel parts in industries such as automotive, aerospace, and manufacturing, ensuring precise temperature control, energy efficiency, and reliable performance.

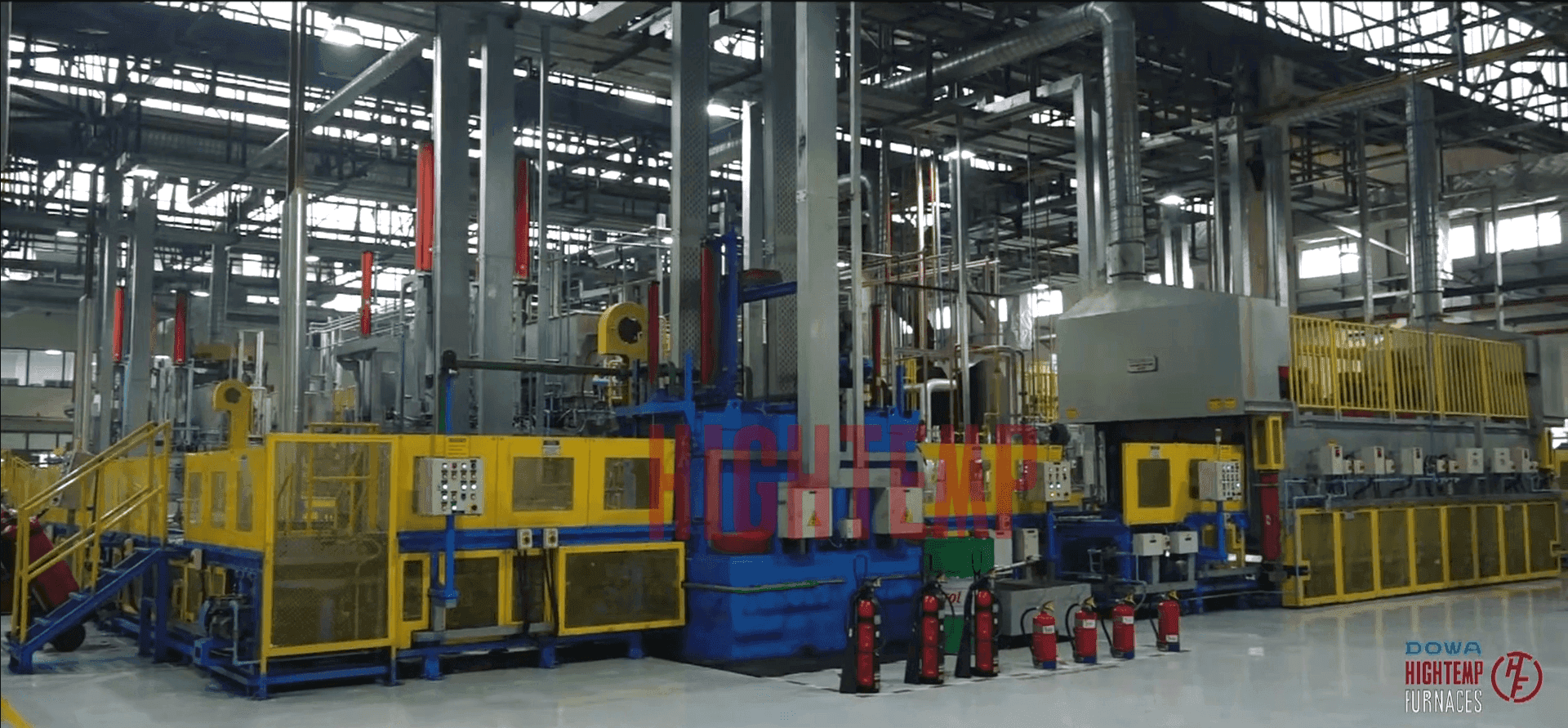

The HIGHTEMP Continuous Hardening and Tempering Furnace is a cutting-edge solution designed for high-volume heat treatment applications. Engineered to deliver precision, efficiency, and reliability, this furnace seamlessly integrates the hardening and tempering processes, meeting the demands of industries where consistent quality and performance are crucial. With a temperature range of 850°C to 1,100°C for hardening, the furnace ensures precise austenitization to achieve maximum hardness. For tempering, it operates between 150°C and 650°C, effectively relieving stresses and reducing brittleness to enhance toughness while maintaining strength.

The Continuous Tempering Furnace is designed for efficient tempering of steel components at temperatures ranging from 190°C to 600°C, offering production capacities of 250 kg/hr to 1500 kg/hr and featuring a mesh belt conveyor system for uniform heat treatment, precise temperature control, energy efficiency, and automation, making it ideal for industries like automotive, aerospace, and manufacturing to process components such as gears, shafts, springs, and fasteners made from materials like carbon steel, alloy steel, tool steel, and spring steel, while ensuring improved mechanical properties, durability, and high productivity.