- Achieves exact carburising depth for enhanced wear resistance.

- Batch Furnace design ensures consistent temperature distribution for uniform carburising and hardening.

- Even heating and cooling cycles reduce the risk of distortion or warping in treated components.

The Continuous Tempering Furnace is designed for efficient tempering of steel components at temperatures ranging from 190°C to 600°C, offering production capacities of 250 kg/hr to 1500 kg/hr and featuring a mesh belt conveyor system for uniform heat treatment, precise temperature control, energy efficiency, and automation, making it ideal for industries like automotive, aerospace, and manufacturing to process components such as gears, shafts, springs, and fasteners made from materials like carbon steel, alloy steel, tool steel, and spring steel, while ensuring improved mechanical properties, durability, and high productivity.

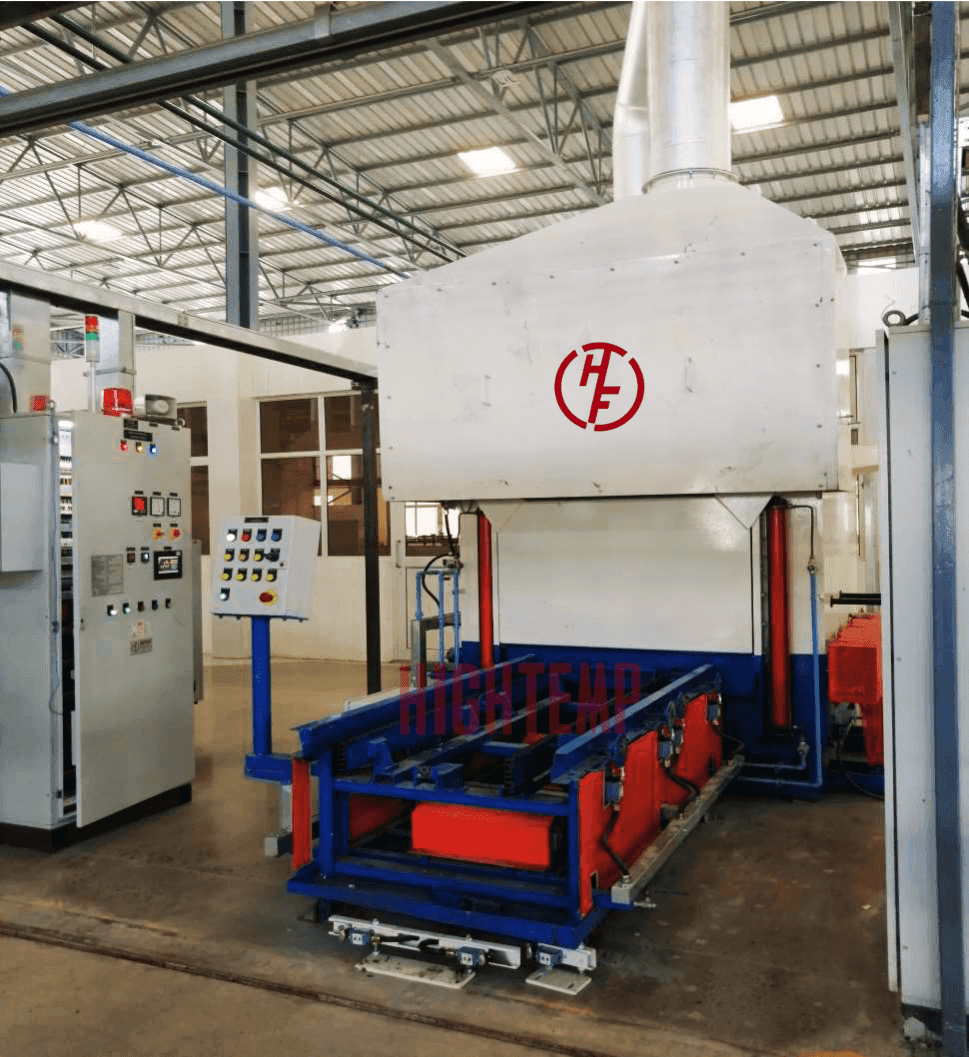

The HIGHTEMP Hardening and Tempering Furnace is an advanced industrial system specifically designed to enhance the mechanical properties of metal components such as gears, shafts, tools, and dies, through a precise process that involves first heating the metals to high temperatures for hardening, followed by a controlled cooling and a subsequent tempering cycle. This dual functionality process significantly increases the hardness and wear resistance of components, while also improving their toughness and fatigue strength. Suitable for a variety of material grades including, but not limited to, 4140 steel, 4340 steel, and AISI D2 tool steel, this furnace is indispensable in industries such as automotive, aerospace, and industrial machinery, where precise and consistent heat treatment is crucial for producing high-performance parts that can withstand extreme conditions and demanding applications. Equipped with advanced control systems for accurate temperature regulation, uniform heating for consistent results, and an energy-efficient design, the HIGHTEMP Hardening and Tempering Furnace optimizes productivity while maintaining stringent quality standards, making it a cost-effective solution for modern manufacturing needs.

HIGHTEMPs Tempering Furnaces is a Chamber Furnace designed for operating at temperatures ranging from 100°C to 650°C to achieve desired mechanical properties. It also features production capacities ranging from 200 kg to 2500 kg gross per batch. The heating and circulation system ensures uniform heat distribution, for every steel parts in industries such as automotive, aerospace, and manufacturing, ensuring precise temperature control, energy efficiency, and reliable performance.